When you start a whole-house custom cabinetry project, you are immediately faced with two big questions: Is it safe? and Will it last? Navigating the maze of technical codes like MDF, Plywood, E0, and ENF can be overwhelming for any homeowner.

Table of Contents

ToggleIn this guide, we’ll break down the latest health standards and material science to help you make an informed investment for your home.

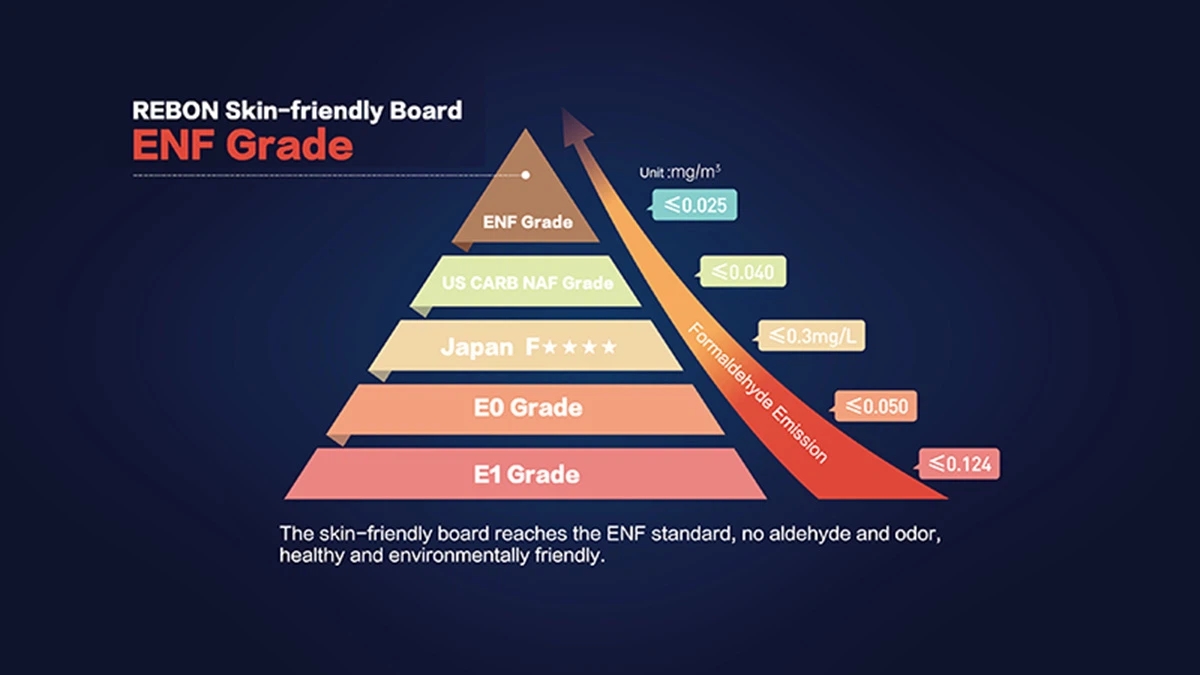

1. The Health Battle – Understanding E1, E0, and ENF Standards

The most critical aspect of modern cabinetry isn’t the color—it’s the Formaldehyde Emission Level. Formaldehyde is a colorless gas used in wood glues that can cause respiratory issues and is a known carcinogen. To protect consumers, the industry uses specific grading systems.

1. E1 Grade: The Mandatory Minimum

- Emission Limit: ≤ 0.124 mg/m³

- Definition: This is the mandatory “safety ceiling” for wood-based panels. Any board sold for indoor use must meet this standard at a minimum. While safe, it may still produce a noticeable “new furniture smell” in poorly ventilated spaces.

2. E0 Grade: The Premium Benchmark

- Emission Limit: ≤ 0.050 mg/m³

- Definition: Long considered the gold standard for high-end furniture, E0 boards emit less than half the formaldehyde of E1. For most family homes, E0 provides an excellent balance of safety and cost.

3. ENF Grade: The World’s Strictest Standard

- Emission Limit: ≤ 0.025 mg/m³

- Definition: ENF stands for “Extra No Formaldehyde.” Introduced in the 2021 Chinese national standard (GB/T 39600-2021), it is currently the most stringent limit globally—even stricter than CARB Phase 2 in the US.

- Why it matters: ENF boards typically use MDI (formaldehyde-free) adhesives. It is the top choice for nurseries, bedrooms, and homes with sensitive individuals.

Pro Tip: “Zero Formaldehyde” is a marketing myth. Natural wood contains trace amounts of formaldehyde. Look for NAF (No Added Formaldehyde) certifications instead of “Zero” claims.

4. Formaldehyde Emission Standards Comparison: E1 vs. E0 vs. ENF

To help you decide which board is right for your budget and health needs, here is a breakdown of the current industry standards (based on the latest GB/T 39600-2021 criteria):

| Grade Standard | Emission Limit (mg/m³) | Safety Level | Best For… |

|---|---|---|---|

| E1 Grade | ≤ 0.124 | Mandatory Safety Line | Living rooms, ventilated hallways, and rental properties. |

| E0 Grade | ≤ 0.050 | High Health Standard | Master bedrooms, kitchens, and high-end residential projects. |

| ENF Grade | ≤ 0.025 | World’s Strictest Limit | Children’s rooms, nurseries, and poorly ventilated apartments. |

*Note: The ENF standard (Extra No Formaldehyde) is currently considered the most stringent formaldehyde limit in the global wood-based panel industry.

2. The Core Materials – Choosing Between MDF, Plywood, and Particle Board

Once you’ve settled on the safety standard, you need to choose the “skeleton” of your cabinets. Different rooms require different physical properties.

1. MDF (Medium-Density Fiberboard)

MDF is made by breaking down wood into fine fibers and pressing them with resin. It is the “Artist’s Board.”

- Best for: Painted or lacquered cabinet doors and intricate carvings.

- Pros: Extremely smooth surface, no grain patterns, easy to shape.

- Cons: Heavy and poor moisture resistance; it will swell if exposed to water leaks.

2. Plywood (Multi-Layer Board)

Plywood is constructed by gluing thin layers of wood veneers in alternating directions. It is the “Structural Workhorse.”

- Best for: Cabinet carcasses in “wet zones” like kitchens and bathrooms.

- Pros: Exceptional screw-holding power and high moisture resistance.

- Cons: Generally more expensive than particle board.

3. Particle Board / Chipboard

Created from wood chips and shavings, high-density particle board is the Global Industry Standard for high-end European cabinetry.

- Best for: Wardrobe bodies and large shelving units.

- Pros: Highly stable (won’t warp), cost-effective, and uniform density.

- Cons: Cannot be used for complex decorative carvings.

3. Material Comparison Matrix

| Material | Common Name | Ideal Use Case | Standard Recommendation |

|---|---|---|---|

| MDF | Density Board | Decorative Doors / Molding | E0 or ENF |

| Plywood | Multi-layer Board | Kitchen & Bath Carcasses | E1 or E0 |

| Particle Board | Chipboard | Bedroom Wardrobes | ENF |

4. Why Edge Banding Is Your Secret Safety Net ?

Even the best board needs proper “sealing.” Edge banding covers the raw edges of the board, not only for aesthetics but to lock in any trace emissions.

- EVA: Traditional glue method; visible seams.

- PUR: Moisture-resistant glue; nearly invisible seams.

- Laser Banding: The gold standard. It uses a laser to melt the edge strip directly to the board, creating a permanent, airtight seal.

Conclusion: Buying with Confidence

Don’t just listen to the salesperson. Always ask to see the CMA/CNAS Test Report for the specific batch of boards. By combining ENF-grade materials with Laser Edge Banding, you are ensuring your home is both beautiful and healthy. Would you like a downloadable PDF checklist of these standards to take with you to your next showroom visit?Experience Global Excellence with PA Home

At PA Home, we transform spaces with precision-engineered cabinetry that meets the world’s highest safety standards. Operating from two state-of-the-art production bases in Indonesia, China, and a Showroom in UAE, we specialize in one-stop whole-house solutions, including premium kitchen cabinets, wardrobes, and walk-in closets.

Whether you require E0 or ENF grade eco-friendly boards, our global service network ensures seamless delivery and installation. With over 1,000+ successful project cases worldwide, we are the trusted partner for homeowners, developers, and designers alike.

Why Choose PA Home?

- Global Reach: Manufacturing hubs in Indonesia, China, and UAE for efficient global logistics.

- Full Customization: One-stop service for kitchens, closets, and whole-house joinery.

- Health First: Certified boards ranging from E1 to ultra-low emission ENF standards.

Ready to elevate your home? Whether you are looking for a bespoke furniture consultation or interested in our wholesale and franchise opportunities, PA Home is ready to assist.

Frequently Asked Questions

1. Is ENF-grade board worth the extra cost compared to E0?

Yes, especially for high-density living areas or sensitive occupants. While E0 is very safe, ENF (Extra No Formaldehyde) represents the pinnacle of environmental health, using formaldehyde-free MDI glues. If you are furnishing a child’s bedroom or a nursery with limited ventilation, the peace of mind offered by ENF is a valuable long-term investment in indoor air quality.

2. Can I use MDF for my kitchen cabinet carcasses?

It is generally not recommended. While MDF is excellent for decorative doors due to its smooth finish, it is susceptible to moisture. For kitchen “carcasses” (the internal boxes), Plywood or High-Density Particle Board is a better choice as they offer superior structural stability and moisture resistance in high-humidity environments.

3. How can I verify if my cabinets are truly ENF or E0 certified?

Don’t rely solely on showroom labels. Always ask your supplier for a formal CMA or CNAS Test Report specifically for the batch of boards used in your project. Reputable manufacturers like PA Home provide transparent documentation that matches the batch number on the boards to ensure authenticity.

4. Does "No Added Formaldehyde" (NAF) mean the board is 100% formaldehyde-free?

Technically, no. All natural wood contains trace amounts of formaldehyde. However, NAF means that no additional formaldehyde-based resins were used during the manufacturing process. This results in emission levels that are often undetectable, making it the safest option available on the market.

5. Why is edge banding so important for formaldehyde safety?

Think of edge banding as a protective seal. High-quality banding (like PUR or Laser Banding) creates an airtight barrier that prevents the trace chemicals inside the board from “off-gassing” into your home. Even a standard board can be made much safer with superior laser edge banding technology.

Related posts:

- Particle Board vs Plywood , Mdf and Solid Wood: Key Differences and Choosing

- Custom Kitchen Cabinets for Landed Houses in Indonesia

- The Best Materials for Kitchen Cabinets Guide: Countertops, Doors, Shelves, and Decorative Panels

- Top 10 Custom Cabinet Companies in Indonesia 2026

- What is the Standard Door Sizes?A Complete Types of Door Sizes.