Best WPC Door Supplier in China

What Are WPC Doors?

Table of Contents

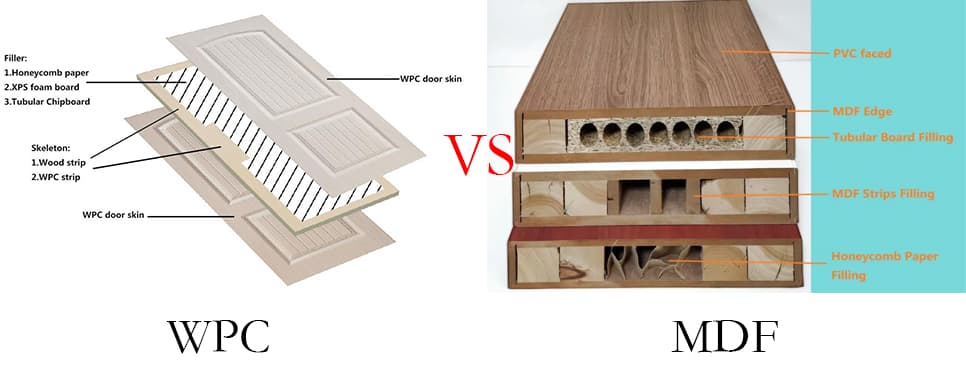

ToggleWood Plastic Composite (WPC) doors are an innovative and sustainable solution for those looking for the benefits of wood combined with the durability of plastic. WPC is a composite material made from a mixture of wood fibers, plastic polymers, and other additives. This combination results in a product that has the appearance of wood but the strength, water resistance, and low maintenance properties of plastic.

WPC doors are widely used in both residential and commercial settings for their aesthetic appeal and functional benefits. These doors come in various finishes and designs, making them an ideal choice for contemporary interior designs. They are highly resistant to moisture, rot, and pests, making them an excellent option for areas with high humidity or fluctuating temperatures. Additionally, WPC doors are environmentally friendly, as they are made from recycled materials and can be fully recycled after their life cycle.

The Advantages of Choosing WPC Doors

- Durability and Strength: WPC doors are incredibly durable and can withstand the rigors of everyday use.

- Water Resistance: WPC doors are highly resistant to moisture, making them suitable for bathrooms, kitchens, and other damp areas.

- Low Maintenance: WPC doors require minimal maintenance, unlike traditional wooden doors.

- Eco-Friendly: Made from recycled materials, WPC doors are an environmentally friendly option.

- Versatility in Design: WPC doors come in a variety of designs, colors, and finishes to suit any aesthetic preference.

Why Are WPC Doors Manufactured in China?

The WPC door supply chain in China is a well-established and highly efficient system that benefits from the country’s advanced manufacturing capabilities, access to raw materials, and robust logistics infrastructure. As global demand for sustainable building materials continues to rise, China is poised to remain the leader in WPC door production and export. With companies like PA Home leading the way, the future of WPC doors in China looks promising, offering both quality and innovation to customers worldwide.

1. Raw Material Sourcing

The first step in the WPC door supply chain is the sourcing of raw materials, which mainly consist of wood fibers, plastic polymers, and other additives. China has a well-established network of suppliers for these materials, making it the primary hub for WPC door production.

Wood fibers

China is one of the largest producers of wood products globally, providing an abundant supply of wood fibers. These fibers are often sourced from both domestic forests and international suppliers. The Chinese government has implemented regulations to ensure sustainable forestry practices, helping to reduce environmental impact.

Plastic Polymers

Plastic polymers, such as polyethylene and polypropylene, are key components of WPC. China is one of the largest manufacturers of plastic materials, benefiting from a robust petrochemical industry. The availability of plastic polymers at competitive prices is a significant advantage for Chinese manufacturers.

Additives

In addition to wood fibers and plastic polymers, various additives, such as stabilizers, UV inhibitors, and colorants, are essential for enhancing the performance and appearance of WPC doors. These additives are widely available in China, contributing to the country’s competitive edge in WPC door production.

2. Manufacturing Process

Once the raw materials are sourced, the next phase in the supply chain is the manufacturing process. China is known for its advanced manufacturing technologies and automation, which play a critical role in producing high-quality WPC doors at scale.

Extrusion Technology

The primary manufacturing method for WPC doors involves extrusion, where wood fibers and plastic are combined and forced through a mold to form the door panels. China’s manufacturing facilities are equipped with state-of-the-art extrusion machines, allowing for the efficient production of large quantities of WPC doors with consistent quality.

Molding and Pressing

In addition to extrusion, some manufacturers use molding and pressing techniques to shape WPC panels. These processes allow for more detailed and intricate designs, which are popular in high-end WPC door products.

Surface Finishing

After the WPC panels are formed, they undergo various surface treatments to improve their appearance and durability. These can include painting, laminating, or coating with finishes such as PVC, veneer, or lacquer. Chinese manufacturers invest heavily in these finishing processes, ensuring that their WPC doors meet global aesthetic standards.

3. Logistics and Distribution

Logistics and distribution are critical components of the WPC door supply chain in China. Given China’s massive production capacity and its position as a leading exporter of WPC doors, the country has developed a highly efficient logistics network to handle the transportation of goods both domestically and internationally.

Domestic Logistics

Within China, the logistics infrastructure is highly developed, with efficient road, rail, and water transport networks. This allows manufacturers to easily source raw materials and distribute finished products to various regional markets.

International Shipping

As one of the largest exporters of WPC doors, China has a vast network of ports and shipping lines to handle international orders. Ports such as Shanghai, Shenzhen, and Ningbo are crucial to the export of WPC doors. Many manufacturers in China maintain partnerships with logistics companies to ensure timely and cost-effective delivery to global markets.

Customs and Import/Export Regulations

China’s government has set up favorable trade policies and free trade zones to encourage the export of building materials, including WPC doors. These policies help reduce tariffs and simplify customs procedures, making it easier for Chinese manufacturers to reach international markets.

4. Market Demand and Trends

The demand for WPC doors in China and globally is driven by several factors:

Sustainability Trends

The growing demand for eco-friendly building materials has contributed to the rise of WPC doors. With a focus on reducing deforestation and promoting recycling, WPC doors are seen as a sustainable alternative to traditional wooden doors.

Economic Growth

China’s rapid economic growth and urbanization have led to increased demand for construction materials, including WPC doors. As more buildings are constructed, both residential and commercial, the need for durable, low-maintenance doors has risen.

Global Export Markets

China’s WPC door manufacturers not only supply the domestic market but also export to regions such as North America, Europe, and the Middle East. These global markets value the cost-effectiveness, durability, and sustainability of WPC doors, which drives demand for Chinese-made products.

5. Challenges and Opportunities

While the WPC door supply chain in China is efficient and competitive, there are also challenges that manufacturers must address:

Raw Material Costs

Fluctuations in the prices of wood fibers and plastic polymers can impact the cost of WPC door production. Manufacturers need to monitor these costs closely and find ways to manage price volatility.

Environmental Regulations

As global awareness of environmental issues grows, Chinese manufacturers must adhere to stricter environmental standards. This includes reducing emissions from production processes and ensuring that the materials used in WPC doors are sustainably sourced.

Innovation and Design

To stay competitive, Chinese manufacturers must continue to innovate and offer a diverse range of designs. Customers are increasingly looking for customized and unique products, and WPC doors must evolve to meet these changing demands.

Why PA Home is the Best WPC Door Supplier in China ?

1. Extensive Product Range

PA Home offers a wide selection of WPC doors, ensuring that customers can find the perfect solution for their needs. From traditional designs to modern, sleek styles, PA Home’s WPC doors are versatile and can be tailored to meet specific aesthetic preferences.

2. Superior Quality

PA Home utilizes state-of-the-art production techniques and strict quality control processes to ensure every door meets the highest standards. PA Home’s WPC doors are known for their durability, stability, and water resistance.

3. Sustainability Commitment

PA Home is committed to sustainability, making its WPC doors from recycled wood fibers and plastic polymers to reduce the environmental impact of production.

4. Customization Options

PA Home offers a wide range of customization options to meet the specific needs of their clients, including custom sizes, colors, finishes, and designs.

5. Competitive Pricing

Despite offering premium-quality WPC doors, PA Home remains committed to providing their products at competitive prices, making them an ideal choice for both small and large-scale projects.

6. Global Reach

With a strong export network, PA Home supplies its WPC doors to countries all over the world, including the Middle East, Europe, and North America.

7. Excellent Customer Service

PA Home’s dedicated team provides exceptional customer service, ensuring a smooth purchasing experience from consultation to post-installation support.

Conclusion

Choosing the right WPC door supplier is crucial to ensuring that you get the best value for your investment. With its cost-effective solutions, high-quality products, and commitment to sustainability, PA Home has earned its place as the best WPC door supplier in China. Whether you’re looking for a single door for your home or need bulk orders for a large project, PA Home’s extensive product range, competitive pricing, and customization options make it the go-to choice for WPC doors in China.

By selecting PA Home, you are not only getting a top-quality product but also supporting a brand that values environmental sustainability and customer satisfaction. If you’re in the market for WPC doors, PA Home is undoubtedly the best choice for your needs.

Contact PA Home to Custom Your WPC Doors

FAQs

1.What is a WPC door and why is it preferred in construction?

WPC (Wood Plastic Composite) doors are a combination of wood fibers and plastic polymers. They offer the aesthetic appeal of wood with the durability, moisture resistance, and low maintenance properties of plastic. WPC doors are preferred in construction because they are eco-friendly, highly durable, and ideal for areas with high humidity, such as bathrooms and kitchens.

2.Why is China the main hub for WPC door production?

China is the primary hub for WPC door production due to its competitive pricing, access to raw materials, and advanced manufacturing technologies. With a robust supply chain, efficient logistics, and a large labor force, Chinese manufacturers can produce high-quality WPC doors at scale, making them an attractive option for global markets.

3.How does China ensure sustainable production of WPC doors?

China has implemented environmental regulations to ensure sustainable production of WPC doors. Manufacturers use recycled wood fibers and plastic polymers, contributing to eco-friendly production practices. Additionally, China is working on reducing carbon emissions and minimizing waste in the manufacturing process, making WPC doors a greener alternative to traditional materials.

4.What are the main advantages of choosing WPC doors?

The advantages of WPC doors include their high durability, resistance to moisture and pests, low maintenance requirements, and eco-friendly nature. These doors are suitable for both residential and commercial applications, offering long-lasting performance and a wide variety of design options. They are particularly ideal for humid areas due to their water resistance.

5.How does PA Home contribute to the global WPC door market?

PA Home is a leading WPC door supplier in China, offering a wide range of high-quality WPC doors. With advanced manufacturing technologies, a commitment to sustainability, and competitive pricing, PA Home is a top choice for customers looking for durable and eco-friendly door solutions. The company supplies WPC doors to various international markets, maintaining a strong reputation for quality and customer service.

Related posts:

- What is the Standard Door Sizes?A Complete Types of Door Sizes.

- 12 Latest Modern Front Door Design Ideas in Indonesia

- Rough Door Opening Dimensions for Different Types of Doors

- How Tall Is a Standard Door?Standard Door Height Guide

- Popular Entrance Door Types in Indonesia Trends Materials and Design 2025